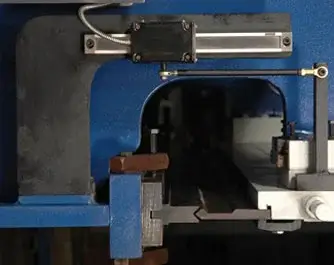

NuGEN Machineries Limited offers Numerically controlled Trimans NC Hydraulic Press Brake Machine from their state of the art manufacturing plant. The tough, robust and strong welded structure is made out of IS 2062 Gr. B. Silicon killed and Ultrasonically tested steel plates to withstand continuous stress and strain under full load at minimum deflection. Equipped with renowned European make Touch Screen Cybelec Controller, Servo Motor, Servo Drive and high precision Magnetic Linear Scale & Ball Screws.

The controller memorizes 792(=8 bends per program * 99 programs) stroke positions to store most popular bends, stroke length, stores height of 20nos. of punches & 30nos. of die to avoid faulty programming & allows skipping a step in program if the bend is not required on the job.

Fitted with two axes NC controller viz. Y-axis (for Depth and angle control) and X-axis for( back gauge positioning)

Programmable NC back gauge with variable speed.

Enables operator to bend jobs with 1 to 8 bends on each edge in one set up.

Automatic retraction of back gauge on pinch point.

Can accommodate more axes especially ADU with Wila Wedges (Optional).

Manual marking is totally eliminated due to NC gauging.

Reduced material handling time.

Manual marking is totally eliminated and Reduces material handling time.