NuGEN Machineries Limited offers Trimans Conventional Hydraulic Press Brakes Twin Cylinder (Rear mounted) Hydraulically Operated. Two rear mounted Hydraulic Cylinders are synchronized by a unique Hydro-mechanical design ensures uniform bending tonnage through linkages, offering distinct advantages of over load protection. Electro-Hydraulic Controls protect machine and tooling from damage due to misuse or overload. Longer strokes enable use of wider combination of tooling and versatile operations. Emergency switch is provided to reduce chances of accidents and to avoid job rejections. Slow speed while bending reduces impact on materials and gives better bending quality and accuracy. Faster approach and return speeds save time to enhance the production.

Trimans Conventional Hydraulic Press Brakes are offered with OSHA workstation for selection of ‘AUTO’ , ‘INCH’ & ‘SINGLE CYCLE AUTO’ mode of operations, along with a pair of Foot Switches, Sheet supports, Manual back gauge, multi way Die & standard Punch and Centralized Lubrication system with Hand pump.

Last but not the least; the raw material used for the structure is tasted ultrasonically, physically & chemically.

A tough, well dimensional structure made out of grade IS 2062 Gr. B, ultrasonically tested steel plates to withstand continuous with least deflection full load.

Rugged torsion tube ensures parallel movement of ram avoiding need for complicated and costly servo hydraulics.

Accuracy of ram movement with special five piece guide system with non-metallic lubrication free liners for longer life.

Three speeds reduces idle travel time to improves productivity.

Noiseless operation and least impact load on tools and foundation.

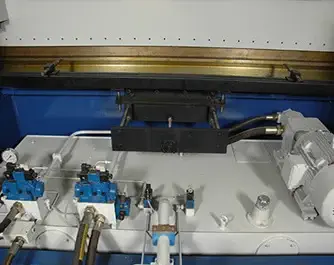

Low system pressure facilitates less power consumption and more hydraulic seal life; thus reduces operating cost and maintenance free from leakages.