NuGEN Machineries Limited offers Trimans CNC Synchro Hydraulic Press Brakes comes with Three Axes (Y1-Y2-X) Alpha Numeric Controller from Europe, advanced German Hydraulics, CNC Back Gauge and Standard set of Hardened and Ground Tooling from Italy. The Hydraulic Systems are specially designed for Press Brakes with Close loop controlled Proportional Valves for Synchronizing and Pressure Control. The Compact Manifold Block eliminates the Leakage Chances.

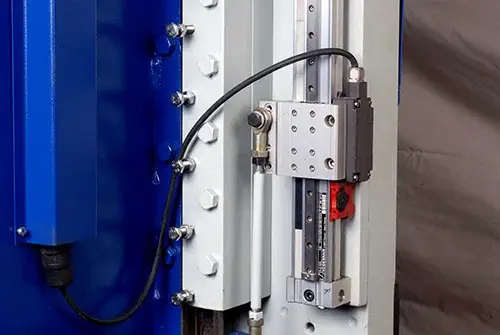

The high precision Imported Linear Scales are fitted on the Steel Frame attached to Machine Bed and it is independent of the side frame. This steel frame supports the sensors which takes positional readings directly from the Ram on the centre line of the Main Pressure Cylinder. The Scales are Self Aligned type fitted with Bearings which always give correct Position of the Upper Tool with respect to Lower Tool. These Scales are mounted on both sides of the CNC Synchro Hydraulic Press Brakes Machine in combination with the Y1 and Y2 axes control, thereby providing accurate synchronization between the Cylinders to 0.01 mm.

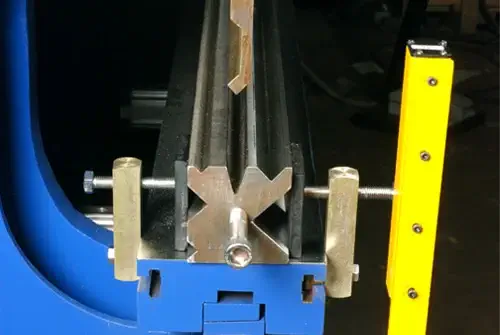

The CNC Press Brake Machine has a precision Heavy Duty Back Gauge with AC Servo Synchronous Motor and Ball Screws, designed to give long service life with better and consistent accuracy. The Gauge Heads are adjustable with quick release Manual Clamps with double dovetail location which ensures precise repositioning.

Last but not the least; the raw material used for the structure is tasted ultrasonically, physically & chemically.

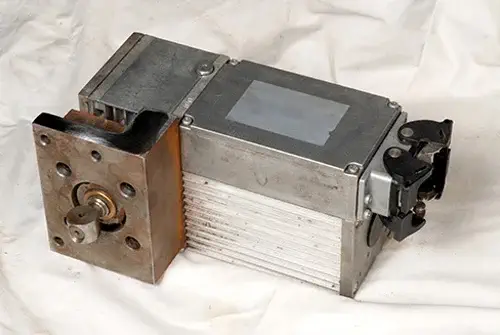

The Alpha – Numeric CNC Controllers offered on the CNC Press Brake Machine are top of the line, user friendly ,easy to use and dedicated Controller from Europe. It can control up to 4 Axes. It is fitted with Monochrome Screen and Key Board with Large Keys. It also controls the Pressure and Crowning. It offers all the functions which are necessary for compliance with the international safety regulations. Its features include Programming of Bending Angle up to 0.1 Deg. Resolution, with Automatic Calculation of Bending Force and Depth according to Material thickness, type and desired bending angle. It ensures full protection against concentrated load on Tooling. It is also possible to program the Stroke, Work Speed (10% to 100%), Return Speed (10% to 100%) to make release of Heavy / Very Wide Jobs Smoother.

The CNC Synchro Press Brakes Machine can be supplied with optional features such as Crowning Systems (Manual/ Motorized), advanced 2D/ 3D display, CNC Controls with Multi Axes and Bending Software as Option.

Programming of stroke, work speed (10% to 100%), return speed (10% to 100%) to make release of heavy or very wide plates smoother.

Manual marking is totally eliminated and Reduces material handling time.

Programming of bending angle upto 0.1 degree resolution, with automatic calculation of bending force & desired bending angle, ensures full protection against concentrated load on toolings.

Repetitive accuracy in the beam stopping is ± 0.01 mm.

Back Gauge retraction on pinch point.

Full Control of positioning & speeds of the ram